A defoamer is a chemical processing aid that eliminates or mitigates the amount of foam produced during industrial operations, such as chemical processing or effluent treatment. Defoamer is a term commonly used to encompass all types of foam control additives, including antifoams and air release agents. Whereas defoamers remove any foam that has manifested, antifoaming agents preclude foam from emerging in the first place. Air release agents are added to a solution to bring any entrained gases to the surface so that they may be dispelled.

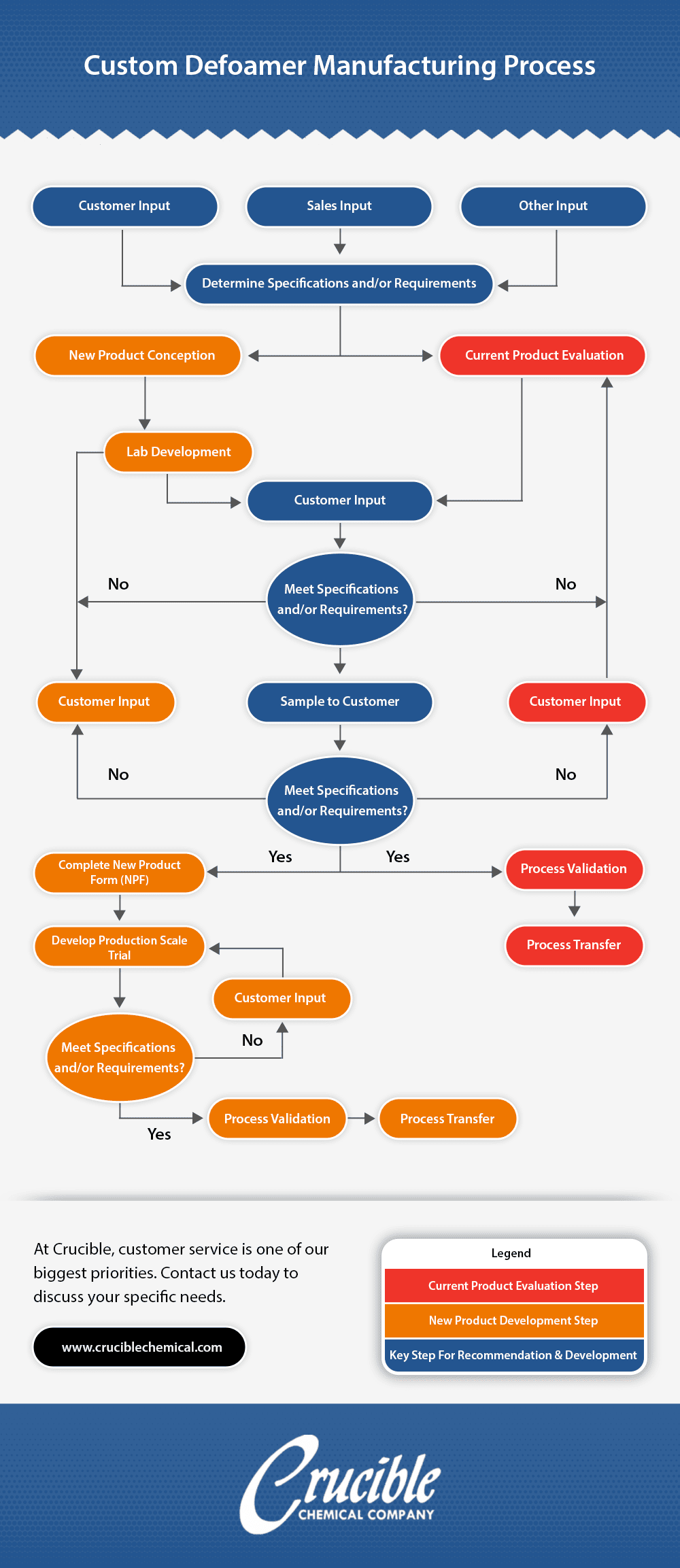

At Crucible Chemical, we offer a range of foam control solutions that can be customized, adapted or built from the ground up to meet the requirements of your unique application. We understand that every application is different and that our standard defoamers and antifoaming agents, while often effective in a broad range of systems, may not always meet every need for complex or unique operations. We’ve created custom defoamers and antifoaming agents to address an expansive range of industrial challenges. Our experienced staff has the tools and expertise necessary to develop and manufacture defoamers and antifoam solutions for even the most complex situations.