Defoamer concentrates are designed to be further diluted or compounded in order to make ready-to-use foam control additives. They are an economical and environmentally friendly way for specialty chemical formulators to create foam control products for internal use or resale.

For a defoamer concentrate to be ultimately effective, it has to be formulated to promote both product stability and effectiveness upon further dilution and compounding. Additionally, proper guidance on blending down with mineral oils, water, surfactants, and/or thickeners is critical to the formulator’s success.

Crucible Chemical Company is a trusted manufacturer of specialty chemicals; we create defoamers for chemical compounders serving a variety of industries. Our technical staff has considerable expertise in end-use applications and welcomes the opportunity to work with compounders on new developments.

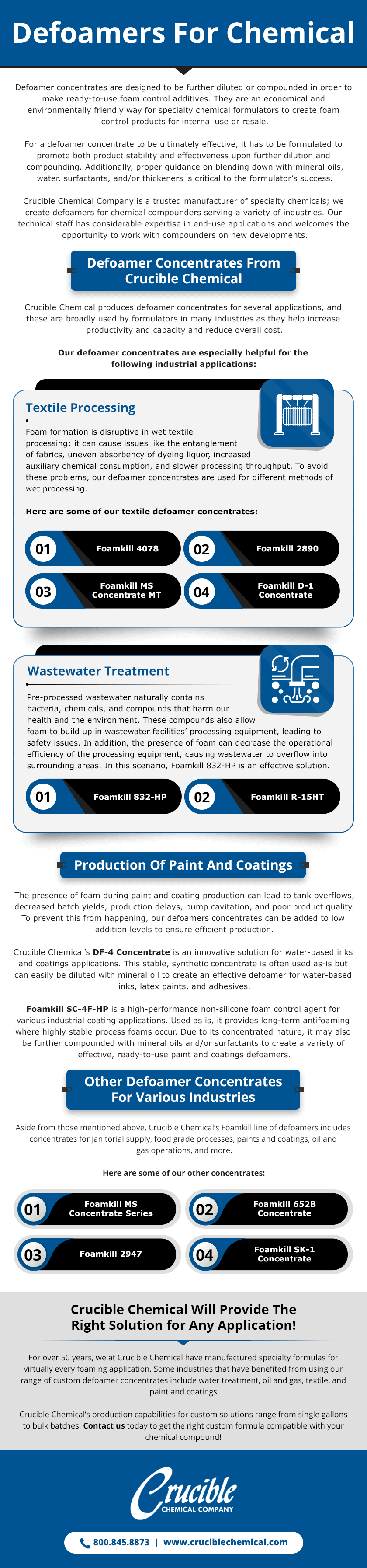

Defoamer Concentrates From Crucible Chemical

Crucible Chemical produces defoamer concentrates for several applications, and these are broadly used by formulators in many industries as they help increase productivity and capacity and reduce overall cost.

Our defoamer concentrates are especially helpful for the following industrial applications:

Textile Processing

Foam formation is disruptive in wet textile processing; it can cause issues like the entanglement of fabrics, uneven absorbency of dyeing liquor, increased auxiliary chemical consumption, and slower processing throughput. To avoid these problems, our defoamer concentrates are used for different methods of wet processing.

Here are some of our textile defoamer concentrates:

- Foamkill 4078: This concentrate is 100 % non-silicone and is applicable for wet textile processing, particularly on pressurized dyeing of synthetics and blends. This Foamkill product can also be formulated into wetting agents, scours, and other textile auxiliaries.

- Foamkill 2890: This is also a non-silicone defoamer concentrate designed for dilution with water and colloid thickeners for general use.

- Foamkill MS Concentrate MT: This defoamer concentrate is an effective organo-silicone concentrate for formulating defoamers for high and low-temperature applications. It requires no additional emulsifier or thickener for stable dilutions. This concentrate is effective in many wet processing applications, particularly carpet dyeing, scours, and acrylic binders

- Foamkill D-1 Concentrate: This is an all-organic, non-silicone formula. It can be diluted with mineral concentrate oil for use as either a pulp-type or textile defoamer.

Wastewater Treatment

Pre-processed wastewater naturally contains bacteria, chemicals, and compounds that harm our health and the environment. These compounds also allow foam to build up in wastewater facilities’ processing equipment, leading to safety issues. In addition, the presence of foam can decrease the operational efficiency of the processing equipment, causing wastewater to overflow into surrounding areas. In this scenario, Foamkill 832-HP is an effective solution.

Foamkill 832-HP is an exceptionally high solid, fortified silicone emulsion that works across all temperatures and pHs up to 11, allowing it to have broad application usage. It is also easily diluted in water and, depending on the intended activity, additional thickeners, which extend its shelf life and stability.

Foamkill R-15HT is designed for high-temperature applications like evaporators with an effective pH range of 14. It is often diluted 50:50 with water.

Production Of Paint And Coatings

The presence of foam during paint and coating production can lead to tank overflows, decreased batch yields, production delays, pump cavitation, and poor product quality. To prevent this from happening, our defoamers concentrates can be added to low addition levels to ensure efficient production.

Crucible Chemical’s DF-4 Concentrate is an innovative solution for water-based inks and coatings applications. This stable, synthetic concentrate is often used as-is but can easily be diluted with mineral oil to create an effective defoamer for water-based inks, latex paints, and adhesives.

Foamkill SC-4F-HP is a high-performance non-silicone foam control agent for various industrial coating applications. Used as is, it provides long-term antifoaming where highly stable process foams occur. Due to its concentrated nature, it may also be further compounded with mineral oils and/or surfactants to create a variety of effective, ready-to-use paint and coatings defoamers.

Other Defoamer Concentrates For Various Industries

Aside from those mentioned above, Crucible Chemical’s Foamkill line of defoamers includes concentrates for janitorial supply, food grade processes, paints and coatings, oil and gas operations, and more. Here are some of our other concentrates:

- Foamkill MS Concentrate Series: These concentrate silicone emulsions require no additional emulsifiers or thickeners to form stable dilute silicone emulsions.

- Foamkill 652B Concentrate: This non-ionic, inert defoamer concentrate can be further compounded with petroleum distillates for general-purpose paint and coatings applications.

- Foamkill 2947: This concentrate is an economical organo-silicone for various high and low-temperature processes. Dilute the formula in two to four parts water to be ready for application.

- Foamkill SK-1 Concentrate: This synthetic concentrate is designed to be further compounded with petroleum oils or pre-thickened water to create effective foam control solutions for pulp & paper, coatings, and monomer stripping applications.

Crucible Chemical Will Provide The Right Solution for Any Application!

For over 50 years, we at Crucible Chemical have manufactured specialty formulas for virtually every foaming application. Some industries that have benefited from using our range of custom defoamer concentrates include water treatment, oil and gas, textile, and paint and coatings.

Crucible Chemical’s production capabilities for custom solutions range from single gallons to bulk batches. Contact us today to get the right custom formula compatible with your chemical compound!